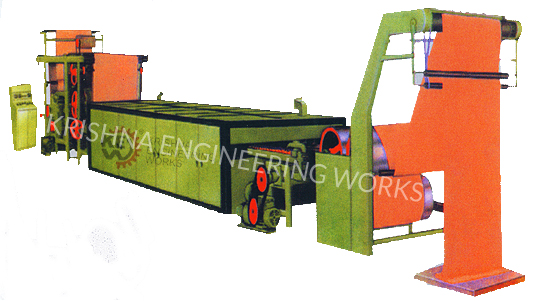

Stenter Machine – Textile Finishing & Heat Setting Solution

Krishna Engineering Works is an Indian manufacturer and exporter of high-quality and advanced textile finishing equipment and Stenter Machines. Our advanced Stenter Machines are popular for heat setting, drying, stretching, and finishing fabrics; all completed precisely, reliably, and consistently.

In addition, we manufacture custom stenter models and spare parts to international standards.

Textile Industry Applications of Stenter Machine

- Heat Setting: Polyester, blends, and technical fabrics; Washing

- Drying: for post dyeing, post bleaching, or post washing

- Finishing: Width control, shrinkage control, and improved hand

- Printing Support: Work with Rotogravure Printing Machine, rotary screen printing, and coating machine

- Stenter Machine Price in India

The stenter machine price is based on:

- Type of machine size/working width

- Number of drying chambers

- Drive system (DC/AC)

- Level of automation, whether manual, semi-auto, and PLC driven

- Optional configurations or attachments

📞 Call +91-8460728298 or email info@kewindia.com for your updated quotation.

Standard Features

Standard Features of Our Stenter Machine

Pneumatic Padding Mangle

- Constructed from heavy-duty MS plate

- Rubber and ebonite squeezing rolls as entry device

- Heavy-duty stainless steel tank with SS guide rolls

- Pneumatic pressure system guarantees even padding and treatment of fabric

Pre-Dryer & Compensator

- 20″–30″ dia. dynamic balance stainless steel cylinders

- Gas heating system, up to four cylinders for maximum contact with the fabric

- Heavy-duty channel structure frame, with guide rolls

- Compensator unit syncs speed between stenter and padding mangle

Bow (or ‘Bias’) & Weft Straightener

- Two curved rubber sleeve expander rolls

- Two ebonite rolls

- Provides full fabric straightening prior to entering the stenter

- Auto feeding device fitted for smooth feed of fabric

Stenter Frame & Clips

- Vibration-free operation with cast iron (CI) legs and supports

- CI cast rails made with precision-lead to clip movement accuracy

- Long-lasting SG iron cast clips that do not damage fabric

- Motorized heavy sprockets with width adjustment system.

Drying Chambers

- MS angles constructed, and insulated with fiberglass wool.

- Pad-insulated panels to contain temperature uniformity

- Chambers extend the total length of the machine to ensure drying consistency.

Selvedge Drying & Plating Unit

- Heavy MS plate frame, with 3 stainless steel heated cylinders for quick drying of fabric selvages with plated-down integrated unit, at the delivered machine end.

Heating System

- Gas-fired heating system with infrared radiant burneres, however it comes standard with copper connections, regulating valves, and needle valves.

- Optional v-type burners with other applicable equipment can be provided for efficiency of heating.

Technical Specification

Technical Specification of Stenter Machine

|

CONTROL |

Control panel for the machine will be fabricated by 16 guage CRC finished with powder coating after defrosting procedure panel will be incorporated with the electric switch gears as per I.S. std of required capacity. |

|

DRIVE |

The machine running with D.C. drive, main drive motor of padding mangle and Stenter are teps D.C. motors reduction gear box is coupled with the main motor of Stenter machine. |

|

FINISHING |

Machine will be finished with red oxide putty & primmer paint and finally with 3 coats of industrial paint. Optionally finished with powder coating process at extra coats. |

|

IMPORTANT NOTE |

The length & width of the Stenter Spare Parts, no. of the chambers, HP. Of D.C. / A.C. motors varies according the buyers requirements operating manual wiring diagram of the control panel & foundation plan will be provided with the machine. We reserve the right to modify / alter the design / specifications without prior notice. |

Video

View our Stenter Machine’s Video

FAQ's

FAQ’s about Stenter Machine

Q1: What does a stenter machine do?

A stenter machine is used to stretch, dry, and heat set fabrics to achieve required width, finish, and dimensional stability.

Q2: What are the benefits of using a stenter?

It provides shrinkage control, fabric stability, improved finishing, and energy-efficient drying.

Q3: What is the difference between a dryer and a stenter?

A dryer removes moisture, while a stenter also controls width, finishes fabric, and heat sets synthetic fibers.

Q4: How to operate a stenter machine?

Operators load fabric at the entry, set temperature, speed, and width parameters on the PLC control panel, and monitor via HMI displays.