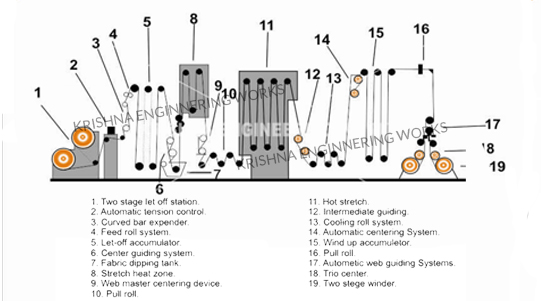

Two Stage Let Off Station in Tyre Cord Dipping Plant. Let Off Station, the first step to perfect and accurate treatment Read More…

Equipments Tyre Cord Dipping Plant

Krishna Engineering Works is a leading manufacturer and exporter of Equipments Tyre Cord Dipping Plant, Tyre Cord and Technical Textile Fabric Dipping Plant / Machine and equipments with meeting the highest performance, safety, environment and cost criteria.It is designed for excellent quality of tire cord fabric for all categories of tyres. Our plant is running at a very high production speed, dipping is the final and most important stage of tyre cord fabric manufacturing and we are dealing on innovative constructions for a longer tyre life. Stronger wires and new cord constructions that lead to lower costs, lower weight and fuel savings

We have been manufacturing high quality and heavy duty Equipments Tyre Cord Dipping Plant, Tire Cord Machinery from last 25 years. All types of Equipments Tyre Cord Dipping Plant from India

1. Two Stage Let Off Station

2. Automatic Tension Control

Automatic Tension Control, featuring as measurement rollers with highly sensitive load cells. High precision tension control Read More…

3. Curved Bar Expander

Curved Bar Expander, designed for tyre cord dipping machine. The Duo expander spreads the fabric in low-tension zones by Read More…

4. Feed Roll System

Feed roll system in tyre cord dipping machine works on important part. Feeding the line by unwinding the fabric, also the Read More…

5. Let-Off Accumulator

Let-Off Accumulator has important role in dipping machine. Fixed dual stations or turret type unwinders with brakes drive Read More…

6. Center Guiding System

The centre guide makes sure that the fabric is guided down the centre of the line. The fabric is centred by the rollers moving Read More…

7. Fabric Dipping Tank

Fabric Dipping Tank designed and built for premium quality of fabric. Low liquor dip tanks, sized to minimize dip solution Read More…

8. Stretch Heat Zone

The radial blowers circulating the air in the treatment chamber are directly coupled to inverter controlled AC motors to Read More…

9. Web Master Centering Device

Web Master Centering design and built in Tyre Cord Dipping Machine for highest level of accuracy. Also, with digital and analogue Read More…

10. Pull Roll

It is featuring as extremely compact digital position controller pull roll Read More…

11. Hot Stretch

Our Tyre Cord Dipping Machine works accurately on fabric for hot stretch function. Hot stretch consistently uniform heat transfer Read More…

12. Intermediate Guiding

Intermediate Guiding has built for effective accuracy. Also, guiding can be done by web edge or centerline. Also, webs are Read More…

13. Cooling Roll System

Double shell cooling rolls are provided to cool the web. It works accurately after the oven with the cooling water moving in Read More…

14. Automatic Centering System

Krishna Engineering Works has designed tyre cord dipping plan with automatic centering system for highest accuracy. Read More…

15. Wind Up Accumulator

Wind up accumulator featuring with International standard of accuracy. Including unique and high quality features Winds up Read More…

16. Pull Roll

It is featuring as extremely compact digital position controller pull roll Read More…

17. Automatic Web Guiding Systems

Our Tyre Cord Dipping Plant designed with high quality Web Guiding System. Featuring with correct the web path and removing Read More…

18. Trio Canter

Tyre Cord Dipping Plant built with premium quality of Trio Canter. The Trio Canter prevents increased cord density at the edges Read More…

19. Two Stage Winder

Two Stage Winder is important part in Tyre Cord Dipping Plant. The precise surface winders produce rolls with required Read More…